Polyethylene (PE): Structure, Properties, and Applications

Polyethylene (PE) is the most widely used commodity plastic. It is available in many different forms depending on the configuration of its molecular chain. Polyethylene is classified as a homopolymer due to the fact that it is made from repeated units of one single type of molecule, ethylene. Polyethylene is a tough, abrasion-resistant plastic that can be easily formed using techniques like injection molding and blow molding. It is typically used for bottles, water tanks, or plastic bags.

This article will discuss the structure, properties, and applications of polyethylene.

What Is Polyethylene (PE)?

Polyethylene refers to a group of thermoplastic homopolymers made up of molecular chains consisting of multiple repeating ethene (IUPC name “ethene”) monomers. Polyethylene and its variants are the most commonly used commodity plastics. Polyethylene is typically used for plastic bags, food/drink containers, and medical applications like knee joints. Polyethylene’s chemical structure consists of repeated monomers made from carbon and hydrogen atoms. There are generally four common types of polyethylene: Ultra- High Molecular Weight Polyethylene (UHMWPE), High-Density Polythene (HDPE), Low-Density Polyethylene (LDPE), and Linear Low-Density Polyethylene (LLDPE).

Who Discovered Polyethylene?

Polyethylene was discovered by Reginald Gibson and Eric Fawcett while reacting ethylene with benzaldehyde in 1933. The first patent for polyethylene was filed in 1936 by a company called Imperial Chemical Industries. Karl Ziegler later invented a process to polymerize HDPE (High-density polyethylene) in 1953, and one of the key catalysts used in the polymerization process is named after him.

What Are the Common Applications of Polyethylene?

Polyethylene and its variants are some of the most widely used plastics and can be found in almost every major industry. The common applications of polyethylene are:

- Bottles

- Water tanks

- Food containers

- Bags

- Pipes and pipe fittings

- Flexible films

- Medical implants

- Ropes

- Fishing nets

- Wear-resistant liners for chutes

What Are the Types of Polyethylene?

The four most common types of polyethylene are described below:

- Ultra-High Molecular Weight Polyethylene (UHMWPE): UHMWPE has a linear molecular chain with no side branching. It has excellent abrasion resistance and is extremely tough, making it well suited to industrial applications. UHMWPE has much longer continuous molecular chains than other polyethylenes, hence the “ultra-high molecular weight” designation.

- High-Density Polythene (HDPE): HDPE material has a linear molecular chain with limited to no branching off the main chain. This allows the polymer chain to fold into a dense structure, allowing for higher packing efficiency and increased crystallinity when compared to LDPE. HDPE is a rigid material with good mechanical properties. It has an opaque appearance.

- Low-Density Polyethylene (LDPE): LDPE does not have the linear molecular structure of HDPE. Instead, the main carbon backbone can have additional branches that have the same form as the basic polyethylene molecule. These branches stop the molecular chain from folding into a densely packed structure, i.e. reducing its packing efficiency compared to the linear structure of HDPE. LDPE is softer than HDPE. It also tends to be transparent, and has low crystallinity.

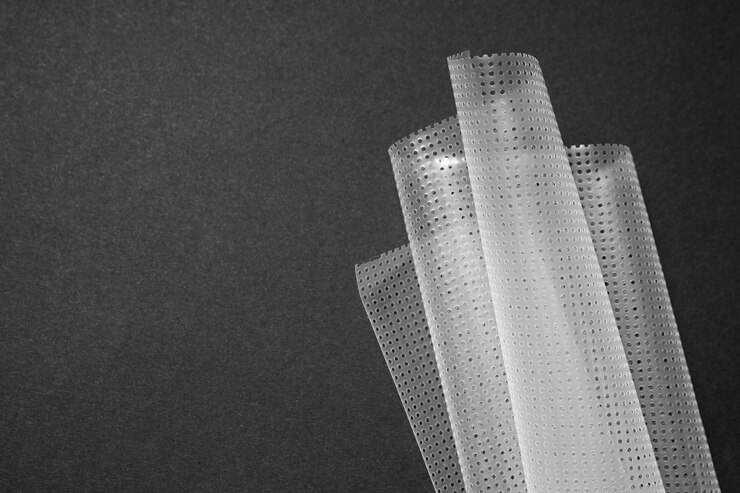

- Linear Low-Density Polyethylene (LLDPE): LLDPE has a similar molecular structure to LDPE. However, its branches are significantly shorter than those found in LDPE. This means that the molecular chains do not entangle themselves as easily. LLDPE has good tensile strength and very high elongation. For that reason, it is often used in stretch films.

Polyethylene is an important thermoplastic polymer, it is abbreviated as PE and is a lightweight, durable, synthetic resin, that has a variety of uses. It is a polymer of ethylene hence the name polyethylene and is the most commonly used plastic. The chemical formula for polyethylene is (C2H4)n. Polyethylene is also called, Polyethene, and Polythene.

In this article, we have covered, the definition of plastic, its structure, chemical properties, applications, and others in detail.

What is Polyethylene?

Polyethylene is a thermoplastic polymer derived from the polymerization of ethylene monomers. It is also considered an addition polymer. It is characterized by a linear structure, consisting of repeating units with two hydrogen atoms attached to each carbon atom.

The linear and simple structure of Polyethylene polymer gives rise to its versatile properties, including flexibility, chemical resistance, and electrical insulating capabilities. With variations like Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE), polyethylene is employed in diverse applications such as packaging, containers, pipes, and medical devices.

Discovery of Polyethylene

Polyethylene was discovered by the German chemist Hans von Pechmann in 1898. However, its commercial production and recognition as a significant polymer began in the 1930s. Imperial Chemical Industries (ICI) in the United Kingdom developed a new method for manufacturing polyethylene in 1933, leading to the creation of low-density polyethylene (LDPE).

Structure of Polyethylene

Repeating Ethylene units made a polymer which is called as a Polyethylene. Ethylene is a hydrocarbon molecule with the chemical formula C2H4, and it consists of two carbon atoms and four hydrogen atoms. When polymerized, ethylene forms long chains of repeating units, resulting in the creation of polyethylene.

Polyethene Molecular Structure

The molecular structure of polyethylene is based on the repeating unit derived from its monomer, ethylene. Ethylene (C2H4) is a simple hydrocarbon with a double bond between two carbon atoms and two hydrogen atoms attached to each carbon. When ethylene undergoes polymerization, it forms a long chain of repeating units.

- Chemical Formula for Polyethylene: (C2H4)n, where “n” represents the number of repeating units in the polymer chain.

Types of Polyethylene

Following are the some major types of the Polyethylene,

- Low-Density Polyethylene (LDPE)

- High-Density Polyethylene (HDPE)

- Linear Low-Density Polyethylene (LLDPE)

- Medium-Density Polyethylene (MDPE)

- Ultra-High-Molecular-Weight Polyethylene (UHMWPE)

- Crosslinked Polyethylene (PEX)

Let’s see each of them in detail,

Low-Density Polyethylene (LDPE)

- Structure: LDPE has a highly branched structure, with numerous short branches off the main polymer chain.

- Properties:

- Low density (hence the name) and a relatively low melting point.

- Flexible and stretchable.

- Transparency and good electrical insulating properties.

- Applications:

- Packaging films, plastic bags, containers, squeezable bottles, and toys.

High-Density Polyethylene (HDPE)

- Structure: HDPE has a more linear structure with fewer branches compared to LDPE.

- Properties:

- Higher density and a higher melting point than LDPE.

- Stiffer, more rigid, and stronger.

- Excellent chemical resistance.

- Applications:

- Containers for chemicals, pipes, geomembranes, plastic lumber, and bottles for milk and detergent.

Linear Low-Density Polyethylene (LLDPE)

- Structure: LLDPE has a structure that falls between LDPE and HDPE, with both short and long branches.

- Applications:

- Flexible packaging films, trash bags, agricultural films, and liners for ponds and landfills.

Medium-Density Polyethylene (MDPE)

- Structure: MDPE falls between LDPE and HDPE in terms of density and branching.

- Properties:

- Moderate density and toughness.

- Used in gas pipes, fittings, and packaging films.

- Applications :

- Gas pipes, fittings, packaging films, and industrial applications.

Ultra-High-Molecular-Weight Polyethylene (UHMWPE)

- Structure:UHMWPE has an extremely high molecular weight, leading to exceptional strength and impact resistance.

- Properties:

- High strength-to-weight ratio, excellent abrasion resistance.

- Self-lubricating properties.

- Applications:

- Bulletproof vests, medical implants, bearings, ropes, and high-performance components.

Crosslinked Polyethylene (PEX)

- Structure: PEX is produced by crosslinking HDPE or LDPE to improve heat and chemical resistance.

- Properties:

- Enhanced temperature resistance and flexibility.

- Used in plumbing for hot and cold water distribution.

- Applications:

- Plumbing pipes, radiant floor heating systems, and insulation.

Properties of Polyethylene

Properties of Polyethylene is studied under two parts, physcial properties of polyethylene, chemical properties of ethylene and they are added below in detail.

Physical Properties of Polyethylene

Following are the physical properties of polyethylene,

- Density: Polyethylene can have different densities depending on the type. For example, LDPE has a low density, while HDPE has a higher density. The density affects the material’s buoyancy and mechanical properties.

- Melting Point: The melting point of polyethylene varies with its type. HDPE typically has a higher melting point compared to LDPE. The melting point influences the material’s processing conditions and thermal stability.

- Flexibility: LDPE is known for its flexibility and elasticity, making it suitable for applications like plastic bags. HDPE, while still flexible, is generally more rigid than LDPE.

- Transparency: LDPE is often more transparent than HDPE. However, both types can be manufactured with varying levels of transparency.

- Crystallinity: Polyethylene can have crystalline and amorphous regions. The degree of crystallinity affects the material’s mechanical properties, with higher crystallinity contributing to stiffness and strength.

- Color: Polyethylene is typically white or translucent. However, it can be pigmented or dyed to achieve various colors.

- Electrical Insulation: Polyethylene is a good electrical insulator, making it suitable for electrical and electronic applications.

- Tensile Strength: Polyethylene exhibits good tensile strength, allowing it to withstand pulling forces without breaking.

- Impact Resistance: Polyethylene is known for its high impact resistance, making it suitable for applications where the material may experience sudden loads or impacts.

Chemical Properties of Polyethylene

Following are the physical properties of polyethylene

- Chemical Inertness: Polyethylene is chemically inert and does not react with most substances. It is resistant to acids, bases, and many organic solvents.

- Water Resistance: Polyethylene is resistant to moisture and does not absorb water, making it suitable for outdoor applications.

- Oxidation Resistance: Polyethylene exhibits good resistance to oxidation, contributing to its durability and long-term stability.

- UV Resistance: Polyethylene has good resistance to ultraviolet (UV) radiation, making it suitable for outdoor applications without significant degradation due to sunlight exposure.

- Thermal Insulation: Polyethylene has good thermal insulation properties, making it suitable for certain thermal applications.

- Biological Resistance: Polyethylene is generally resistant to biological degradation, although specific additives may impact its biodegradability.

- Chemical Stability: Polyethylene maintains its chemical stability over a wide range of temperatures, contributing to its versatility in various environments.

- Recyclability: Polyethylene is recyclable, and recycling processes can be employed to reduce waste and promote sustainability.

- Flammability:Polyethylene is generally not highly flammable, and its flammability can be influenced by additives and processing conditions.

Uses of Polyethylene

Polyethylene is a versatile polymer with a wide range of applications due to its favorable combination of properties, including flexibility, chemical resistance, and ease of processing. Some common uses of polyethylene include:

- Packaging: Polyethylene is widely used in packaging applications, such as plastic bags, shrink wrap, and stretch film. Its flexibility and ability to form airtight seals make it ideal for protecting and containing various products.

- Containers and Bottles: HDPE and LDPE are commonly used to manufacture containers and bottles for beverages, household cleaners, personal care products, and industrial chemicals.

- Plastic Pipes: HDPE is widely used in the production of pipes for water and gas distribution. Its high strength, chemical resistance, and flexibility make it suitable for plumbing and infrastructure projects.

- Agricultural Films: LDPE and LLDPE are used in the production of agricultural films, including greenhouse films, mulch films, and silage bags. These films help improve crop yield and protect crops from pests and adverse weather conditions.

- Construction Materials: Polyethylene is used in construction materials such as plastic sheets, geomembranes, and insulation materials. HDPE, in particular, is employed in the construction of liners for landfills and ponds.

- Toys and Sporting Goods: Polyethylene is used to manufacture a variety of toys, including dolls, building blocks, and outdoor play equipment. Its durability and safety contribute to its popularity in the toy industry.

- Medical Devices and Packaging: UHMWPE is used in the production of medical implants and devices due to its biocompatibility and wear resistance. Additionally, LDPE is used in medical packaging for items like sterile wraps and tubing.

- Cable Insulation: HDPE and LDPE are used as insulation materials for electrical and telecommunications cables due to their electrical insulating properties and durability.

- Trash Bags and Liners: LDPE and LLDPE are commonly used in the production of trash bags and liners due to their flexibility, strength, and resistance to tearing.

- Automotive Components: Polyethylene is used in the automotive industry for various components, including fuel tanks, bumpers, and interior trim parts. HDPE, in particular, is employed for fuel tanks due to its chemical resistance.