Introduction

The oil and petrochemical industry plays a crucial role in the global economy, providing essential products that fuel transportation, power industries, and create everyday consumer goods. However, the handling and transportation of oil derivatives, liquefied petroleum gas (LPG), and petrochemical products come with inherent risks. This article outlines best practices for ensuring safety and efficiency in these processes, supported by guidelines and case studies.

Understanding Oil Derivatives and Petrochemical Products

Oil derivatives include a wide range of products such as gasoline, diesel, kerosene, and lubricants, while petrochemical products encompass chemicals derived from petroleum, including plastics, fertilizers, and synthetic fibers. Proper handling of these substances is vital to prevent accidents, environmental damage, and financial losses.

Best Practices for Handling Oil Derivatives

- Training and Certification

All personnel involved in the handling of oil derivatives should undergo rigorous training and certification. This includes understanding the properties of the materials, emergency response procedures, and the use of personal protective equipment (PPE).

- Use of Proper Equipment

Utilizing appropriate equipment for the handling and transportation of oil derivatives is essential. This includes:

- Pipelines: Regularly inspected and maintained to prevent leaks.

- Tankers: Designed to meet safety standards and equipped with spill containment systems.

- Storage Facilities: Built with secondary containment to manage spills.

- Regular Inspections and Maintenance

Conducting regular inspections and maintenance of equipment and facilities helps identify potential hazards before they lead to incidents. This includes checking for leaks, corrosion, and structural integrity.

- Emergency Response Planning

Developing and implementing an emergency response plan is crucial. This plan should include:

- Clear communication protocols.

- Designated emergency response teams.

- Regular drills to ensure preparedness.

Best Practices for Handling LPG

- Safe Storage

LPG should be stored in well-ventilated areas away from ignition sources. Storage tanks must be regularly inspected for leaks and corrosion.

- Leak Detection Systems

Installing leak detection systems can provide early warnings of gas leaks, allowing for prompt action to mitigate risks.

- Transportation Safety

When transporting LPG, it is essential to:

- Use specialized vehicles designed for gas transport.

- Ensure drivers are trained in handling emergencies related to LPG.

Best Practices for Handling Petrochemical Products

- Hazard Communication

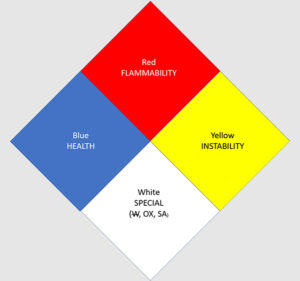

Employers must ensure that all workers are aware of the hazards associated with petrochemical products. This includes proper labeling and access to Material Safety Data Sheets (MSDS).

- Environmental Controls

Implementing environmental controls, such as vapor recovery systems, can minimize emissions and reduce the environmental impact of petrochemical handling.

- Waste Management

Proper disposal of waste products generated during petrochemical processing is essential to prevent environmental contamination.

Case Studies

Case Study 1: The Texas City Disaster

In 2005, a series of explosions at the BP refinery in Texas City resulted in 15 fatalities and numerous injuries. The investigation revealed failures in safety management and emergency response. This tragedy underscores the importance of rigorous safety protocols and regular training.

Case Study 2: LPG Leak in Canada

In 2013, a significant LPG leak in a Canadian facility led to an evacuation and extensive property damage. The incident highlighted the need for effective leak detection systems and emergency preparedness.

Conclusion

The handling and transportation of oil derivatives, LPG, and petrochemical products require strict adherence to safety practices. By implementing comprehensive training, utilizing proper equipment, and maintaining robust emergency response plans, companies can significantly reduce risks and ensure the safety of their operations. Learning from past incidents through case studies can further enhance safety measures and promote a culture of continuous improvement in the industry.

References

- Occupational Safety and Health Administration (OSHA)

- American Petroleum Institute (API)

- National Fire Protection Association (NFPA)